TWO MONTHS

INDUSTRIAL TRAINING REPORT

Held at

ENGINEERING TECHNOLOGY SOLUTIONS(ETS)

KURUKSHETRA (HRY.)

Submitted

in partial fulfilment of the requirement for the 6th Semester

Curriculum Degree of Bachelor of

Technology in

“INSTITUTE OF INSTRUMENTATION ENGINEERING”

Of

Kurukshetra University,

Kurukshetra

DEPARTMENT OF INSTRUMENTATION ENGINEERING

INSTITUTE OF INSTRUMENTATION ENGINEERING, KURUKSHETR UNIVERSITY

, KURUKSHETRA

SUBMITTED

BY:-

contents

·

certificate

·

acknowledgement

·

objectivE of

training

COMPANY profile

·

INTRODUCTION

·

OBJECTIVES

programmable

logic controllers

·

PLC

BASICS

·

HISTORY

·

OLD WAYS

·

IT IS NOT HARD TO IMAGINE

·

EARLIER

·

Need for PLC

·

Advantages of PLC

·

AUTOMATION

· What is a PLC?

·

GUTES INSIDE

·

PLC OPRATION

· PLC Basic COMPONENTS

·

About Inputs and Outputs of PLC

·

ANOLOG VERSUS DIGITAL INPUTS & OUTPUTS

·

HOW PLC REMOVING COMPLEXITY?

·

RELAY

·

REPLACING RELAY

·

WHAT IS CONTROL PROGRAM?

·

PLC Architecture

·

About Ladder Logic

·CONTACTS

· INDUSTRIAL SENSOR

ACKNOWLEDGEMENT

I have reached to this opportunity to thank all those who

have been guide me on interval of my training & this report to completion.

I am also grateful to Sh., Director of ETS.

I am grateful to all staff members of

ETS

for this remarkable and outstanding cooperation.

They help me and guide me for right

path of training.

I am also very thankful to my friends

who contributed a lot in solving the problems & devoted their valuable time

in spite of their own studies.

I take this opportunity to bring on

record the inspiration, help and indulgence.

OBJECTIVES OF TRAINING

·

The

main objective of training is to get first hand technical and practical

knowledge of PLC

The main purpose is that

the students would become familiar with industrial environment so that they can

take up future challenges when they turn up in an industry with good

confidence.

·

The

students will thus understand the flow of control and information in an

industry.

·

This

eight weeks training has been introduced in degree Engg. Courses for the

enhancement of students’ administrative and professional knowledge about their

respective fields.

·

After

completion of their degree courses this training experience will help them to

make their workplace stronger in the ever-competitive job fields.

COMPANY PROFILE

INTRODUCTION

ETS has grown to be a company with the

potential to become the strategic partners for world-wide customers for their

software needs for Semiconductors & Embedded.

ETS has a passionate team consisting of professionals having good experience.

The team has diversified experience and expertise in both product development

and services model and value the significance of Customer Satisfaction

and Meeting Deadlines.

With key emphasis on Quality,

ETS follows through the Quality Processes during Product Development and

Project Execution.

ETS

with it strong determination and commitment for providing quality machinery and

relentless customer care seeks an opportunity to serve your esteemed organization

with its range of products.

OBJECTIVES

1) Complete understanding of customer requirement in

respect of their end products and necessary technology for it.

2) Ensuring to meet customer specification, time schedule

and any requirement to match existing equipment by strictly adopting line

concept, selection of equipment designed manufacturing, inspection installation

and commissioning norms and procedures.

3) All equipment in a line to be designed and supplied to

ensure their working in synchronous mode for achieving the desired end product

specification.

4) To ensure reliability, aesthetics, easy maintenance,

equipment and operator safety, environmental protection and easy of human

stress.

5) Selection of manufacturing practices to ensure “right

first time” output.

6) To maintain and demonstrate the QUALITY ASSURANCE

CONCEPT.

7) Ultimately, improvement in human relation both

internal and external through team work principal, better social communication

and relation development efforts.

PROGRAMMABLE LOGIC CONTROLLER

PLC Basic

History:-

The PLC was invented in response to the needs of

the American automotive industry. Before the PLC, control, sequencing, and

safety interlock logic for manufacturing automobiles and trucks was

accomplished using relays, timers and dedicated closed-loop controllers. The

process for updating such facilities for the yearly model change-over was very

time consuming and expensive, as the relay systems needed to be rewired by

skilled electricians. In 1968 GM Hydramatic (the automatic transmission

division of General Motors) issued a request for proposal for an electronic replacement

for hard-wired relay systems.

The winning proposal came from Bedford Associates

of Bedford, Massachusetts. The first PLC, designated the 084 because it was

Bedford Associates eighty-fourth project, was the result. Bedford Associates

started a new company dedicated to developing, manufacturing, selling, and

servicing this new product: Modicon, which stood for MODular DIgital Controller.

One of the very first 084 models built is now on

display at Modicon's headquarters in North

Andover, Massachusetts.

It was presented to Modicon by GM, when the unit was retired from nearly twenty

years of uninterrupted service.

The automotive industry is still one of the

largest users of PLCs, and Modicon still numbers some of its controller models

such that they end with eighty-four.

In the 1960s and 1970s, industry was beginning to see

the need for automation. Industry saw the need to improve quality and increase

productivity. Flexibility had also become a major concern. Industry

needed to be able to change processes quickly to meet the needs of the

consumer.

OLD WAYS

·

There was always

a huge wiring panel to control the system.

·

Inside the panel

there were masses of electromechanical relays.

·

These relays were

all hardwired together to make the system work.

· Hardwiring means that an electrician had to install wires

between the connections of the relays.

·

An engineer would

design the logic of the system and electricians would be given a blueprint of

the logic and would have to wire the components together.

It is not hard to imagine

·

That the engineer

made a few small errors in his/her design.

·

That the

electrician may have made a few errors in wiring the system.

·

That there are

few bad components in the system.

Earlier ways

·

The only way to

see everything was correct was to run the system.

· Troubleshooting

was done by running the actual system. This was a very time-consuming process.

· No product could

be manufactured while the wiring was being changed and system had to be

disabled for wiring changes. This means that all the production personnel

associated with that production line were without work until the system was

repaired.

·

The control

system was based on mechanical relays.

·

Mechanical

devices are usually the

weakest links in the systems. Mechanical devices have moving parts that can

wear out. If one relay failed, the electrician might have to troubleshoot the

whole system again. The system was down again until the problem was found and

corrected.

· Another problem

with hardwired logic is that if a change must be made, the system must be

shutdown and the panel rewired. If a company decided to change the sequence of

operations (even a minor change), it was a major expense and loss of production

time while the system was not producing parts.

Need for PLC

·

Due to the

disadvantages of the hardwired control panels industry saw the need to replace

them and introduce PLCs.

· Increased

competition to manufacturers to improve

both quality and Productivity.

·

Flexibility,

rapid changeover and reduced

downtime became important.

·

Industry realized

that a computer could be used for logic instead of hardwired relays. Computer

could take the place of huge, costly, inflexible, hardwired control panels.

·

If changes in the

system logic or sequence of operations were needed, the program of the computer

could be changed instead of rewiring.

·

Imagine

eliminating all the downtime associated with wiring changes.

· Imagine being

able to completely change how a system operated by simply changing the software

in the computer.

·

High

reliability

Advantages of PLC

·

Small space

requirements

·

Computing

capabilities

·

Reduced costs

·

Ability to

withstand harsh environments

·

Expandability

Automation

Automation is the use of computers to control industrial machinery

and processes, replacing human operators. It is a step beyond mechanization,

where human operators are provided with machinery to help them in their jobs.

The most visible part of automation can be said to be industrial robotics.

Some advantages are repeatability, tighter quality control, waste reduction,

integration with business systems, increased productivity and reduction of labor.

Some disadvantages are high initial costs and increased dependence on

maintenance.

By

the middle of the 20th century, automation had existed for many years on a

small scale, using mechanical devices to automate the production of simply

shaped items. However the concept only became truly practical with the addition

of the computer, whose flexibility allowed it to drive almost any sort of task.

Computers with the required combination of power, price, and size first started

to appear in the 1960s, and since then have taken over the vast majority of assembly line

tasks (some food production/inspection being a notable exception).

In most cases specialized

hardened computers referred to as PLCs (Programmable

Logic

Controllers) are used to synchronize the flow of inputs from sensors

and events with the flow of outputs to actuators and events. This leads to

precisely controlled actions that permit a tight control of the process or

machine.

Human-Machine Interfaces

(HMI) are usually employed to communicate to PLCs. e.g.: To enter and monitor

temperatures or pressures to be maintained.

Another

form of automation that involves computers is called test automation,

where computers are programmed to mimic what human testers do when manually

testing software

applications. This is accomplished by using test automation tools

to produce special scripts (written as computer programs)

that tell the computer exactly what to do in order to run the same manual

tests.

Need For Automation:-

Automation

is required because of

·

Shorter

throughput times.

·

Shorter set-up

times.

·

Higher

productivity.

·

Stock reduction.

·

Higher

availability.

·

Better capacity

utilization.

·

Shorter process

change times.

·

Stability and

accuracy of control.

·

Greater

reliability & equipment life.

·

To add

flexibility to process.

What is a PLC?

A PLC (i.e. Programmable Logic Controller) is

a device that was invented to replace the necessary sequential relay circuits

for machine control. The PLC works by looking at its inputs and depending upon

their state, turning on/off its outputs. The user enters a program, usually via

software, that gives the desired results.

PLCs are used in many "real world"

applications. If there is industry present, chances are good that there is a

plc present. If you are involved in machining, packaging, material handling,

automated assembly or countless other industries you are probably already using

them. If you are not, you are wasting money and time. Almost any application

that needs some type of electrical control has a need for a plc.

For example, let's assume that when a switch

turns on we want to turn a solenoid on for 5 seconds and then turn it off

regardless of how long the switch is on for. We can do this with a simple

external timer. But what if the process included 10 switches and solenoids? We

would need 10 external timers. What if the process also needed to count how

many times the switches individually turned on? We need a lot of external

counters.

As you can see the bigger the process the

more of a need we have for a PLC. We can simply program the PLC to count its

inputs and turn the solenoids on for the specified time.

This site gives you enough information to be

able to write programs far more complicated than the simple one above. We will

take a look at what is considered to be the "top 20" plc

instructions. It can be safely estimated that with a firm understanding of

these instructions one can solve more than 80% of the applications in

existence.

That's right, more than 80%! Of course we'll learn more than just these

instructions to help you solve almost all your potential plc applications.

A programmable logic controller,

PLC or programmable controller is a small computer used for automation of real-world processes, such as

control of machinery on factory assembly lines. Where older automated systems

would use hundreds or thousands of relays and cam timers, a single PLC can be programmed

as a replacement.

The PLC is a microprocessor based device with either

modular or integral input/output

circuitry that monitors the status of field connected "sensor" inputs and controls the attached output

"actuators" (motor starters, solenoids, pilot lights/displays, speed

drives, valves, etc.) according to a user-created logic program stored in the

microprocessor's battery-backed RAM

memory. The functionality of the PLC has evolved over the years to include

capabilities beyond typical relay control; sophisticated motion control, process control, Distributed

Control System and complex networking have now been added to the PLC's

list of functions.

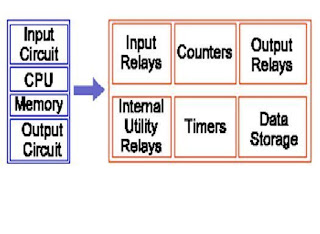

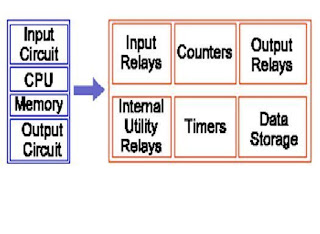

The Guts Inside

The PLC mainly consists of a CPU, memory

areas, and appropriate circuits to receive input/output data. We can actually

consider the PLC to be a box full of hundreds or thousands of separate relays,

counters, timers and data storage locations. Do these counters, timers, etc.

really exist? No, they don't "physically" exist but rather they are

simulated and can be considered software counters, timers, etc. These internal

relays are simulated through bit locations in registers. (More on that later)

What does each part do?

·

INPUT RELAYS-(contacts)

these are connected to the outside world. They physically exist and receive

signals from switches, sensors, etc. Typically they are not relays but rather

they are transistors.

·

INTERNAL UTILITY

RELAYS-(contacts) these do not receive signals from the outside world nor do

they physically exist. They are simulated relays and are what enables a PLC to

eliminate external relays. There are also some special relays that are

dedicated to performing only one task. Some are always on while some are always

off. Some are on only once during power-on and are typically used for

initializing data that was stored.

·

COUNTERS-These

again do not physically exist. They are simulated counters and they can be

programmed to count pulses. Typically these counters can count up, down or both

up and down. Since they are simulated they are limited in their counting speed.

Some manufacturers also include high-speed counters that are hardware based. We

can think of these as physically existing. Most times these counters can count up,

down or up and down.

·

TIMERS-These also

do not physically exist. They come in many varieties and increments. The most

common type is an on-delay type. Others include off-delay and both retentive

and non-retentive types. Increments vary from 1ms through 1s.

·

OUTPUT RELAYS-(coils)

these are connected to the outside world. They physically exist and send on/off

signals to solenoids, lights, etc. They can be transistors, relays, or traces

depending upon the model chosen.

·

DATA

STORAGE-Typically there are registers assigned to simply store data. They are

usually used as temporary storage for math or data manipulation. They can also

typically be used to store data when power is removed from the PLC. Upon

power-up they will still have the same contents as before power was removed.

Very convenient and necessary!!

PLC Operation

A PLC works by continually scanning

a program. We can think of this scan cycle as consisting of 3 important steps.

There are typically more than 3 but we can focus on the important parts and not

worry about the others. Typically the others are checking the system and

updating the current internal counter and timer values.

Step 1-CHECK INPUT STATUS-First

the PLC takes a look at each input to determine if it is on or off. In other

words, is the sensor connected to the first input on? How about the second

input? How about the third... It records this data into its memory to be used

during the next step.

Step 2-EXECUTE PROGRAM-Next

the PLC executes your program one instruction at a time. Maybe your program

said that if the first input was on then it should turn on the first output.

Since it already knows which inputs are on/off from the previous step it will

be able to decide whether the first output should be turned on based on the

state of the first input. It will store the execution results for use later

during the next step.

Step 3-UPDATE OUTPUT STATUS-Finally

the PLC updates the status of the outputs. It updates the outputs based on

which inputs were on during the first step and the results of executing your

program during the second step. Based on the example in step 2 it would now turn

on the first output because the first input was on and your program said to

turn on the first output when this condition is true.

After the third step the PLC goes back to

step one and repeats the steps continuously. One scan time is defined as the

time it takes to execute the 3 steps listed above.

PLC Basic Component

Power Supply:

Power Supply:

·

The power supply

is used to supply the power for the central processing unit.

·

Most of the PLCs

operate on 115VAC. This means that input voltage to power supply is 115VAC.

·

On some PLCs

power supply is a separate module and some have integrated on it.

Input section:

·

This section

performs two vital tasks.

·

It takes input

from the outside world and also protects CPU from the outside world.

·

Input devices are

often called Field Devices.

Output section:

·

The output

section of PLC provides connection to the real world output devices.

· The output

devices might be motor starters, lights, coils, valves etc. These are also

called the Field Devices.

·

They can be used

to output analog or digital signals.

About inputs and outputs of

PLC

The input/output (I/O)

system is the section of a PLC to which all of the field devices are

connected. If the CPU can be thought of as the brains of a PLC, then the I/O

system can be thought of as the arms and legs. The I/O system is what actually

physically carries out the control commands from the program stored in the

PLC’s memory.

I/O modules are devices with connection terminals to which the

field devices are wired. Together, the rack and the I/O modules form the

interface between the field devices and the PLC. When set up properly, each I/O

module is both securely wired to its corresponding field devices. This creates

the physical connection between the field equipment and the PLC.

All of the field devices

connected to a PLC can be classified in one of two categories:

• Inputs

• Outputs

Inputs are devices that supply a signal/data to a PLC.

Typical examples of inputs are push buttons, switches, and measurement devices.

Basically, an input device tells the PLC, that something is happening out

here…you need to check this out & see how it affects the control program.

Outputs are devices that await a signal/data from the PLC to

perform their control functions. Lights, horns, motors, and valves are all good

examples of output devices. These devices stay unaffected, until the PLC says;

now you need to turn on or you’d better open up your valve a little more, etc.

EXAMPLE

An input device sends a

signal to a PLC...

An output device

receives a signal from a PLC.....

There are two basic types

of input and output devices:

• Discrete

• Analog

Discrete devices are inputs and outputs that have only two states: on

and off. As a result, they send/receive simple signals to/from a PLC. These

signals consist of only 1s and 0s. A 1 means that the device is on and a 0

means that the device is off.

Analog devices are inputs and outputs that can have an infinite

number of states. These devices cannot only be on and off, but they can also be

barely on, almost totally on, not quite off, etc. These devices send/receive

complex signals to/from a PLC. Their communications consist of a variety of

signals, not just 1s and 0s.

EXAMPLE

The overhead light and switch

we just discussed are both examples of discrete devices. The switch can only be

either totally on or totally off at any given time. The same is true for the

light. A thermometer and a control valve are examples of the other type of I/O

devices/analog. A thermometer is an analog input device because it provides

data that can have an infinite number of states. Temperature isn’t just hot or

cold. It can have a variety of states, including warm, cool, moderate, etc. A

control valve is an analog output for the same reason. It can be totally on or

totally off, but it can also have an infinite number of settings between these

two states.

A discreet can only be on or off, an analog device can be

either on, off or anywhere in between.

Because different input and

output devices send different kinds of signals, they sometimes have a hard time

communicating with the PLC. While PLCs are powerful devices, they can’t always

speak the “language” of every device connected to them. That’s where the I/O

modules we talked about earlier come in. The modules act as “translators”

between the field devices and the PLC. They ensure that the PLC and the field

devices all get the information they need in a language that they can

understand.

Analog

versus digital inputs and outputs

Digital signals behave as switches, yielding

simply an On or Off signal (logical 1 or 0, respectively). These are interpreted

as boolean values by the PLC. Pushbuttons, limit switches, and photo-eyes are

examples of devices providing a digital signal. Analog signals behave as volume

controls, yielding a range of values between On and Off. These are typically

interpreted as integer values by the PLC, with various ranges of accuracy

depending on the device and the number of bits available to store the data.

Pressure transducers, scales and gas leak detectors can provide analog signals.

Digital signals generally use either voltage or current,

where a specific range is denominated as On (logical 1) and another as Off

(logical 0). A typical PLC might use 24VDC I/O (with 24V representing On and 0V

representing Off). Analog signals generally use voltage or current

as well, but do not have discrete ranges for On or Off. They define a range of

valid values, typically the range in which the I/O device operates reliably.

Other methods of signal I/O include serial

communications (typically RS-232 or RS-485), and proprietary

networks like Allen-Bradley's Data Highway, Opto 22's OptoMux or open and

standardised networks like Profibus.

PLCs have a limited number of connections built in

for signals such as digital inputs, digital outputs, analog inputs and analog

outputs. Typically, expansions are available if the base model does not have

sufficient I/O.

The average amount of inputs installed in the

world is three times that of outputs for both analog and digital. The need for

this rises from the PLC's need to have redundant methods to monitor a

instrument to appropriately control another.

Examples

As an example, say the facility needs to store

water in a tank. The water is used as needed, but spilling is not permitted.

The PLC has two digital inputs from float

switches, and a timer. The PLC controls two digital outputs to open and close

the two inlet valves into the tank, and an error light. The valves are one

after the other so that either valve can turn off the water. This means that

the water can be turned off even if one valve breaks. The valves have

repeaters, little sensor switches, so the logic controller can sense whether

they are open or closed.

If both float switches are off (down) the PLC will

open the valves to let more water in, and starts a timer. If both float

switches are on, both valves turn off. When the timer is done, it turns off

both valves anyway, to prevent spills, and if both switches are not on, and

both valves closed, an error light turns on to indicate that a switch or valve

is broken. A test button provides a way to restart the timer and retest the

switches. The maintenance engineer will have a schedule to test such equipment.

Another example might use a load cell (the sensor of a scale) that weighs

the tank and a rate valve. The logic controller would uses a PID feedback loop

to control the rate valve. The load cell is connected to one of the PLC's

analog inputs and the rate valve is connected to one of the PLC's analog

outputs. This system fills the tank faster when there's less water in the

tank. If the water level drops rapidly, the rate

valve can be opened wide. If water is only dripping out of the tank, the rate

valve adjusts to slowly drip water back into the tank.

In this system, the tricky thing is adjusting the

PID loop so the rate valve doesn't wear out from many continual small

adjustments. Many PLCs have a "deadband", a range of outputs in which

no change is commanded. In this application, the deadband would be adjusted so

the valve moves only for a significant change in rate. This will in turn

minimize the motion of the valve, and reduce its wear.

A real system might combine both approaches, using

float switches and simple. valves to prevent spills, and a rate sensor and rate

valve to optimize refill rates

How PLC helps in removing

complexity?

In a traditional industrial

control system, all control devices are wired directly to each other according

to how the system is supposed to operate. In a PLC system, however, the PLC

replaces the wiring between the devices. Thus, instead of being wired directly

to each other, all equipment is wired to the PLC. Then, the control program

inside the PLC provides the “wiring” connection between the devices.

The control program

is the computer program stored in the PLC’s memory that tells the PLC

what’s supposed to be going on in the system. The use of a PLC to provide the

wiring connections between system devices is called soft wiring.

Let’s say that a push

button is supposed to control the operation of a motor. In a traditional

control system, the push button would be wired directly to the motor. In a PLC

system, however, both the push button and the motor would be wired to the PLC

instead. Then, the PLCs control program would complete the electrical circuit

between the two, allowing the button to control the motor.

The soft wiring advantage

provided by programmable controllers is tremendous. In fact, it is one of the

most important features of PLCs. Soft wiring makes changes in the control

system easy and cheap. If you want a device in a PLC system to behave

differently or to control a different process element, all you have to do is

change the control program. In a traditional system, making this type of change

would involve physically changing the wiring between the devices, a costly and

time-consuming process.

Let’s say that two

push buttons, PB1 and PB2, are connected to a PLC. Two pilot lights, PL1 and

PL2, are also connected to the PLC the way these devices are connected now

pressing push button PB1 turns on pilot light PL1 and pressing push button PB2

turns on pilot light PL2. Let’s say that you want to change this around so that

PB1 controls PL2 and PB2 controls PL1. In a traditional system, you would have

to rewire the circuit so that the wiring from the first push button goes to the

second pilot light and vice versa. However, because these devices are connected

to a PLC, making this change is as simple as making a small change in the

control program.

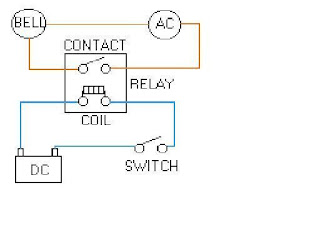

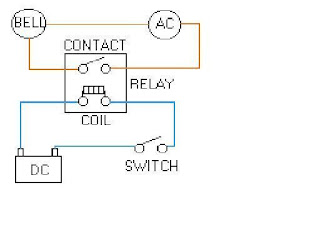

Relays

Now that we understand how the PLC processes

inputs, outputs, and the actual program we are almost ready to start writing a

program. But first let’s see how a relay actually works. After all, the main

purpose of a plc is to replace "real-world" relays.

We can think of a relay as an electromagnetic

switch. Apply a voltage to the coil and a magnetic field is generated. This

magnetic field sucks the contacts of the relay in, causing them to make a

connection. These contacts can be considered to be a switch. They allow current

to flow between 2 points thereby closing the circuit.

Let's consider the following example. Here we

simply turn on a bell (Lunch time!) whenever a switch is closed. We have 3

real-world parts a switch, a relay and a bell. Whenever the switch closes we

apply a current to a bell causing it to sound.

Notice in the picture that we have 2 separate

circuits. The bottom (blue) indicates the DC part. The top (red) indicates the

AC part.

Here we are using a dc relay to control an AC

circuit. That's the fun of relays! When the switch is open no current can flow

through the coil of the relay. As soon as the switch is closed, however,

current runs through the coil causing a magnetic field to build up. This

magnetic field causes the contacts of the relay to close. Now AC current flows

through the bell and we hear it. Lunch time!

A

typical industrial relay

Replacing Relays

Next, let’s use a plc in place of the relay.

(Note that this might not be very cost effective for this application but it

does demonstrate the basics we need.) The first thing that's necessary is to

create what's called a ladder diagram after seeing a few of these it will

become obvious why it is called a ladder diagram. We have to create one of

these because, unfortunately, a plc doesn't understand a schematic diagram. It

only recognizes code. Fortunately most PLCs have software which converts ladder

diagrams into code. This shields us from actually learning the plc's code.

First step- We have to translate all of the items we're using

into symbols the plc understands. The plc doesn't understand terms like switch,

relay, bell, etc. It prefers input, output, coil, contact, etc. It doesn't care

what the actual input or output device actually is. It only cares that it’s an

input or an output.

First we replace the battery with a symbol.

This symbol is common to all ladder diagrams. We draw what are called bus bars.

These simply look like two vertical bars One on each side of the diagram. Think

of the left one as being + voltage and the right one as being ground. Further

think of the current (logic) flow as being from left to right.

Next we give the inputs a symbol. In this basic example we have one real world

input. (I.e. the switch) We give the input that the switch will be connected

to, to the symbol shown below. This symbol can also be used as the contact of a

relay.

(A contact

symbol)

(A contact

symbol)

Next we give the outputs a symbol. In this example

we use one output (i.e. the bell). We give the output that the bell will be

physically connected to the symbol shown below. This symbol is used as the coil

of a relay.

(A coil symbol)

(A coil symbol)

The AC supply is an external supply so we

don't put it in our ladder. The plc only cares about which output it turns on

and not what's physically connected to it.

Second step- We must tell the plc where everything is located. In

other words we have to give all the devices an address. Where is the switch

going to be physically connected to the plc? How about the bell? We start with

a blank road map in the PLCs town and give each item an address .Could you find

your friends if you didn't know their address? You know they live in the same

town but which house? The plc town has a lot of houses (inputs and outputs) but

we have to figure out who lives where (what device is connected where). We'll

get further into the addressing scheme later. The plc manufacturers each do it

a different way! For now let's say that our input will be called

"0000". The output will be called "500".

Final step- We have to convert the schematic into a logical

sequence of events. This is much easier than it sounds. The program we're going

to write tells the plc what to do when certain events take place. In our

example we have to tell the plc what to do when the operator turns on the

switch. Obviously we want the bell to sound but the plc doesn't know that. It's

a pretty stupid device, isn't it!

The picture above is the final converted

diagram. Notice that we eliminated the real world relay from needing a symbol.

It's actually "inferred" from the diagram. Huh? Don't worry; you'll

see what we mean as we do more examples.

What is control

program?

The control program is a

software program in the PLC’s memory. It’s what puts the control in a

programmable controller. The user or the system designer is usually the one who

develops the control program. The control program is made up of things called instructions.

Instructions are, in essence, little computer codes that make the inputs and

outputs do what you want in order to get the

Result you need.

There are all

different kinds of instructions and they can make a PLC do just about anything

(add and subtract data, time and count events, compare information, etc.). All

you have to do is program the instructions in the proper order and make sure

that they are telling the right devices what to do and when to do.

If

you want the system to act differently, just change the instructions in the

control program. Different PLCs offer different kinds of instructions. That’s

part of what makes each type of PLC unique. However, all PLCs use two basic

types of instructions:

• Contacts

• Coils

Contacts are instructions that refer to the input conditions to

the control program, that is, to the information supplied by the input field

devices. Each contact in the control program monitors a certain field device.

The contact waits

For the input to do

something in particular (e.g., turn on, turn off, etc.—this all depends on what

type of contact it is).

A contact is a computer

code that monitors the status of an input coil is a computer code that monitors

the status of an output.

Coils are instructions that refer to the outputs of the

control program that is, to what each particular output device is supposed to

do in the system. Like a contact, each coil also monitors a certain field

device. However, unlike a contact, which monitors the field device and then

tells the PLC what to do, a coil monitors the PLC control program and then tells

the field device what to do. Coil makes the field device to on or off depending

upon the PLC instructions.

Let’s say that turning

on the switch is supposed to turn on the light. In this situation, the PLCs

control program would contain a contact that examines the input device the wall

switch for an on condition and a coil that references the light. When the

switch turns on, the contact will energize, meaning that it will tell the PLC

that the condition it’s been looking for has happened. The PLC will relay this

information to the coil instruction by energizing it. This will let the coil

know that it needs to tell its referenced output the light to turn on.

PLC Architecture

RAM: -

Volatile

User can read or write to the memory

Program memory: -

Store program to

control various processes

Divided into different blocks:

a) Organization Block - Main program

b) Program Block - Subroutines or Calculations

c) Function Block - Special functions

d) Data Block - Temporary data

e) Sequential Block - PLC operations

Timers: -

a) Pulse Timer

b) Extended Pulse Timer

c) On-Delay Timer

d) Extended Delay Timer

e) Off Delay Timer

Counters:

a) Up Counter

b) Down Counter

c)

Up/Down Counter

Flags:

·

Bits, Bytes and

Words used for temporary data storage

PII:

·

Stores status of

all the inputs

PIQ:

·

Process Image

Output

·

Stores status of

all the outputs

System Data Image:

·

Stores information

related to the system like CPU type, CPU make and system bits, bytes, etc.

ROM:

·

Read Only Memory

stores Operating System for PLCs. Operating System is burned into ROM by the

PLC manufacturer. It controls the functions such as the system software that

the user uses to program the PLC.

· ROM is a

non-volatile memory that is when electricity is switched off, the data in the

memory is retained.

Memory Sub module/EEPROM:

· Electrically

Erasable Programmable Read Only Memory. This is a non-volatile memory.

·

EEPROM is used to

store the programs or ladder logics, which can be copied to the PLC.

ALU:

·

Arithmetic &

Logical Unit.

· It performs all

the calculations and logic functions of the PLC. It loads information from PII,

processes it in the accumulator and then transfers the results to the PIQ.

Serial Port:

· This port is used

for communication with the external devices. If the external device understands

some other protocol then we have to use some converter so that both PLC and the

external device are able to understand each other’s language.

PLC programming devices:

·

There are many

devices used to program the PLCs. These devices do not need to be attached to

the PLC once the ladder is written. The devices are just used to write the user

program for the PLC.

·

They may also be

used to troubleshoot the PLC.

About

Ladder Logic

Ladder logic or the Ladder programming language is a

method of drawing electrical logic schematics. It is now a graphical language

very popular for programming programmable logic controllers. It was

originally invented to describe logic made from relays.

A program in ladder logic, also called a ladder

diagram, is similar to a schematic for a set of relay circuits.

Ladder logic is useful because a wide variety of engineers and technicians can

understand and use it without much training.

Ladder logic is widely used to program industrial Programmable

logic controllers, where a series of complex logic checks are required

before something is turned on. Ladder logic is useful for simple but critical

control systems, or for reworking old hardwired relay circuits.

Most providers of programmable logic controllers also

provide associated ladder logic programming systems. Typically, the ladder

logic languages from two different providers will not be compatible; ladder

logic is better thought of as a set of closely related programming languages

rather than one language.

Example of a

simple ladder logic program

The language itself can be seen as a set of connection

between logical checkers (relay contacts) and actuators (coils).

Ladder logic has "contacts" that

"make" or "break" "circuits" to control

"coils."

There are two types of contacts:

--[ ]-- a relay normally open (N/O) contact. This contact

turns on if the relay's coil is on.

--[\]-- a relay normally closed (N/C) contact. This

contact turns off if teh relay's coil is on.

These are switched by a circuit (or more archaically the

"coil" of a relay). They in turn switch a circuit. In a ladder

programmign language, the circuits are represented by a name or number.

The contacts represent electrical switches. They form

logic that can be configured to produce any logical function such as AND,

OR, XOR, NAND, NOR, INV

Here is an example of what one rung in a ladder logic

program might look like. In real life, there would typically be hundreds or

thousands of rungs.

---[ ]-----[ ]---

X

Y

Represents X AND Y, because both X and Y must be on for

the circuit to be on.

----|---[ ]---|------

|

X |

| |

|---[ ]---|

Y

Represents X OR Y, because the circuit will be on if

either X or Y are on.

----|---[\]---|------

|

X |

| |

|---[\]---|

Y

Represents X NAND Y, because the circuit will turn off

only if both X and Y are turned on.

Ladder logic is then used to drive output coils, so that when the preceding

logical functions have been evaluated - the output coil changes state.

--( )-- an N/O output coil

--(\)-- an N/C output coil

For Example

----[ ]---------|--[ ]--|------( )--

X |

Y | S

| |

|--[ ]--|

Z

Realises the function S= X.(Y+Z)

Complex ladder logic is 'read' in the same way as a

western book (left to right). The first point on the left, is the input signal

(or high potential), as each of the lines (or rungs) are evaluated the output

coil of a rung may feed into the next stage of the ladder as an input. In a

complex system there will be many "rungs" on a ladder, which are

numbered in order of evaluation.

1 ----| |-----------|-| |-----|----( )--

X |

Y | S

|

|

|---| |---|

Z

2 ----| |----| |-------------------( )--

S

X T

T=X.S

This represents a slightly more complex system for rung

2. After the first line has been evaluated, the output coil (S) is fed into

rung 2, which is then evaluated and the output coil T could be fed into an

output device (buzzer, light etc..) or into rung 3 on the ladder.

This system allows very complex logic designs to be broken

down and evaluated fairly easily.

For more practical examples see below (my creations

released to wikipedia):

|

|

|

|

|--][------------][-------------------O---|

keysw1

keysw2 door motor

This circut shows the two key switches that security

guards might use to activate motor on a bank vault door. When the normally open

contacts of both switches close, electricity is able to flow to the motor which

opens the door. This is a logical AND.

|

|

|

+-------+ |

|----------------------------+ +----|

| +-------+ |

| Remote receiver |

|-----][------------------------------O---|

|

remote unlock| lock solenoid

|

|-----][------------+

interior switch

This circuit shows the two things that can trigger the

power door locks in my imaginary car. The remote receiver is always powered.

The lock solenoid gets power when either set of contacts is closed. This is a

logical OR.

Since electrical engineers already knew how to read

ladder logic, PLC makers made their systems programmable in ladder logic. This

would allow electrical engineers to read, debug, troubleshoot and write

computer programs for the PLCs which replaced their cabinets full of relays.

Additional Functionality

Additional functionality can be added to a ladder logic

implementation by the PLC manufacturer as a special block. When the special

block is powered, it executes code on predetermined arguments. These arguments

may be displayed within the special block

| |

|

+-------+ |

|-----][---------------------+ A

+----|

| remote unlock +-------+ |

| Remote counter |

| |

|

+-------+ |

|-----][---------------------+ B

+---|

| interior unlock +-------+ |

| Interior counter |

| |

| +--------+ |

|--------------------+ A + B +---------|

+ into C +

+-------- +

Adder

In this example, the system will count the number of

times that the interior and remote unlock buttons are pressed. This information

will be stored in memory locations A and B. Memory location C will hold the

total number of times that the door has been unlocked electronically.

Origin of Ladder

Diagram : -

•

The Ladder

Diagram (LD) programming language originated from the graphical representation

used to design an electrical control system

−

Control decisions

were made using relays.

•

After a while

Relays were replaced by logic circuits

− Logic gates used to make control decisions.

•

Finally CPUs were

added to take over the function of the logic circuits

−

I/O Devices wired

to buffer transistors.

− Control decisions accomplished through programming.

•

Relay Logic

representation (or LD) was developed to make program creation and maintenance

easier

−

Computer based

graphical representation of wiring diagrams that was easy to understand.

− Reduced training and support cost.

−

−

What is a Rung?

•

A rung of ladder diagram code can contain both input and output instructions.

− Input instructions perform a

comparison or test and set the rung state based on the outcome.

−

Normally left justified on the rung.

·

Output instructions examine the rung state and execute some

operation or function.

−

In some cases output instructions can set the rung

state.

−

Normally right justified on the rung.

|

|

Contacts

•

Normally Open

Contact -| |-

–

Enables the rung

to the right of the instruction if the rung to the left is enabled and

underlining bit is set (1).

•

Normally

Closed Contact -|/|-

–

Enables the rung

to the right of the instruction if the rung to the left is enabled and

underlining bit is reset (0).

•

Positive

transition contact -|P|-

–

Enables the right

side of the rung for one scan when the rung on left side of the instruction is

true.

•

Negative

transition contact -|N|-

Enables

the right side of the rung for one scan when the rung on left side of the

instruction is false.

Non Retentive Coils

Non-retentive values or

instructions are reset to some default state (usually 0) after a power cycle

·

Coil -( )-

−

Sets a bit when

the rung is true (1) and reset the bit when the rung is false (0).

·

Negative coil

-( / )-

−

Sets a bit when

the rung is false (0) and resets the bit when the rung is True (1).

−

Not commonly

supported because of potential for confusion.

·

Set (Latch)

coil -(S)-

−

Sets a bit (1) when

the rung is true and does nothing when the rung is false.

·

Reset

(Unlatch) Coil -(R)-

Resets

a bit (0) when the rung is true and does nothing when the rung is false.

Retentive Coils

The referenced bit is

unchanged when processor power is cycled or retentive values or instructions

maintain their last state during a power cycle.

·

Retentive coil

-(M)-

−

Sets a bit when

the rung is true (1) and resets the bit when the rung is false (0)

·

Set Retentive

(Latch) coil -(SM)-

−

Sets a bit (1)

when the rung is true and does nothing when the rung is false

·

Reset

Retentive (Unlatch) Coil -(RM)-

−

Resets a bit (0)

when the rung is true and does nothing when the rung is false

Transition Sensing Coils

•

Positive

transition-sensing coil -(P)-

−

Sets the bit (1)

when rung to the left of the instruction transitions from off (0) to on (1)

−

The bit is left

in this state.

•

Negative

transition-sensing coil -(N)-

−

Resets the bit

(0) when rung to the left of the instruction

transitions from on (1) to off (0)

−

The bit is left

in this state.

Industrial Sensors

Objectives: -

•Need

for sensors

•Examine

types and uses of different industrial sensors

•Digital

and Analog sensors

•Wiring

of sensors

Need: -

In the past operators were the brains

of the equipment. He was the source of all information about the operation of a

process. He could see, hear and feel the problems of operation. Industry is now

using PLCs and computers to control their operations, as they are faster and

accurate than the operator for these tasks. Industrial sensors are used to give

the industrial controllers these capabilities.

Simple sensors can be used by the PLC

to check if the parts are present or absent, to size the parts, even to check

if the product is empty or full and also for the safety of equipment and

operator.

Infect, sensors perform simple tasks

more efficiently and accurately than people do. Sensors are much faster and

make far fewer mistakes.

Contact type:-

The device must contact a part to sense a part.

Example: Limit Switch

Non-Contact type:-

Sensors that can detect the product

without touching the product physically.

Advantages:

1. Their operation is generally

electronic and not mechanical, so they are more reliable and less likely to

fail.

2. Much faster and can perform at high

production rates.

3. You cannot slow down or interfere

with process

We’ll

go in details with Non-Contact type sensors as they are in much use.

Digital Sensors:-

A digital sensor has two states - ON

or OFF. Most applications involve presence/absence and counting. A digital

sensor meets this need perfectly and inexpensively.

Digital

output sensors are either on or off. They generally have transistor outputs. If

the sensor senses an object the output will turn on. The transistor turns on

and allows current to flow. The output

from sensor is usually connected to a PLC input module.

Sensors are available with either normally

closed or normally

Open output contacts. NO contact sensors are off until

they sense an object. NC contact sensors are on until they sense an object.

When they sense an object the output turns off.

Example: Photo sensors (Dark-on, Light-on)

Analog Sensors:-

They are more complex but can provide

much more information about a

process. They are also called linear output sensors.

An

analog sensor senses the parameter and sends a current to the PLC. The output from the analog sensor can be any value

in the range from low to high.

A

4-20mA current loop system can be used for applications where the sensor needs

to be mounted a long distance from the control device. A 4-20mA loop is good to

about 800m.

Example: Temperature, Pressure sensor

# Digital sensors are more widely used because of their

simplicity and ease of use.

Optical Sensors:-

These sensors use light to sense

objects. In the past they somewhat unreliable because they used common light

and were affected by ambient lighting. Today they are very reliable because of

the way they now operate.

All optical sensors function almost in

the same manner. There is a light source

(emitter) and a photo detector to sense the presence or absence of light.

Light-emitting diodes (LEDs) are typically used for the light source. An LED is

a semiconductor diode that emits light. LEDs are a PN-type semiconductor.

Forward biased electrons from N-type material enter the P-type material where

they combine with excess holes. When an electron and a hole combine, energy is

released. These energy packets are called photons. Photons then escape as light

energy. The type of material used for the semi-conductor determines the

wavelength of the emitted light.

Why LEDS are chosen:-

•

Small, sturdy, very efficient and can be turned on and off at the

•

Extremely high speeds.

•

Operate in a narrow wavelength and are very reliable.

•

Not sensitive to temperature, shock or vibration

•

Have almost endless life

Operation:-

The LEDs in sensors are used in a

pulse mode. The emitter is pulsed (turned off and on repeatedly). The “on-time”

is extremely small as compared to the “off-time”.

LEDs

are pulsed for two reasons:

1. So that the sensor is unaffected by

ambient light.

2. To increase the life of the LED.

This can also be called modulation.

Pulsed

light is sensed by the photo detector. Photo emitter and photo receiver are

both “tuned” to the frequency of the modulation. The photo detector sorts out

all ambient light and looks for the pulsed light. Light sources chosen are

typically invisible to human eye. Wavelengths are chosen so that sensors are

not affected by other lightening in the plant. The use of different wavelengths

allows some sensors, called color mark sensors, to differentiate between

colors. The pulse method and the wavelength chosen make optical sensors very

reliable. Optical sensors are available in either light or dark sensing. This

is also called light on or dark-on. Infect many sensors can be switched between

light and dark